Pt. 1 Nuclear Fuel Cycle - Mining

By Julia Strong

Chisme Collective is kicking off Part 1 of a series on the rise of nuclear power in Texas with a look at the beginning of the nuclear fuel cycle: mining.

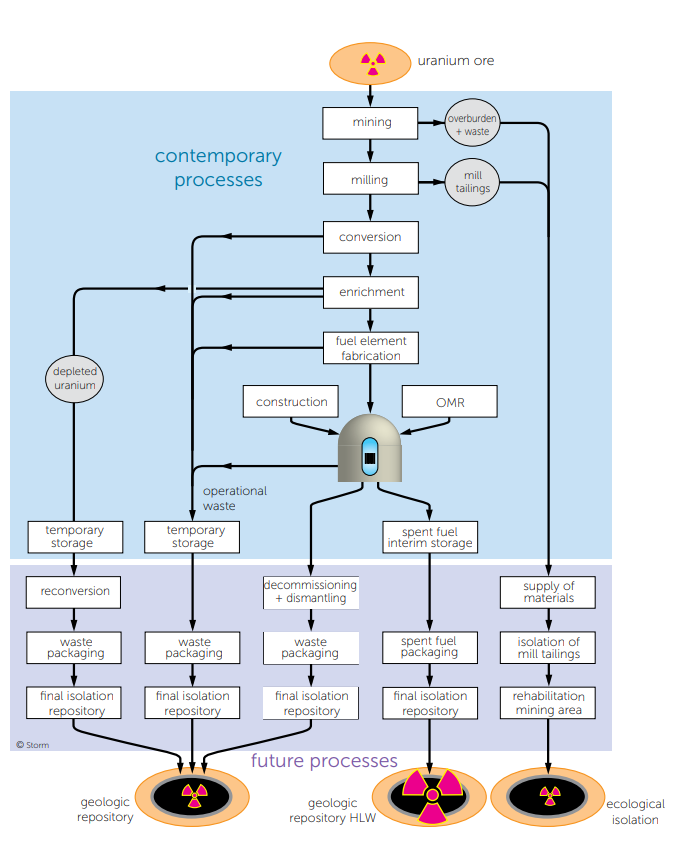

Mining uranium is the first step in supplying a nuclear power reactor with fuel to create energy. This is what’s considered the beginning of the nuclear fuel cycle.

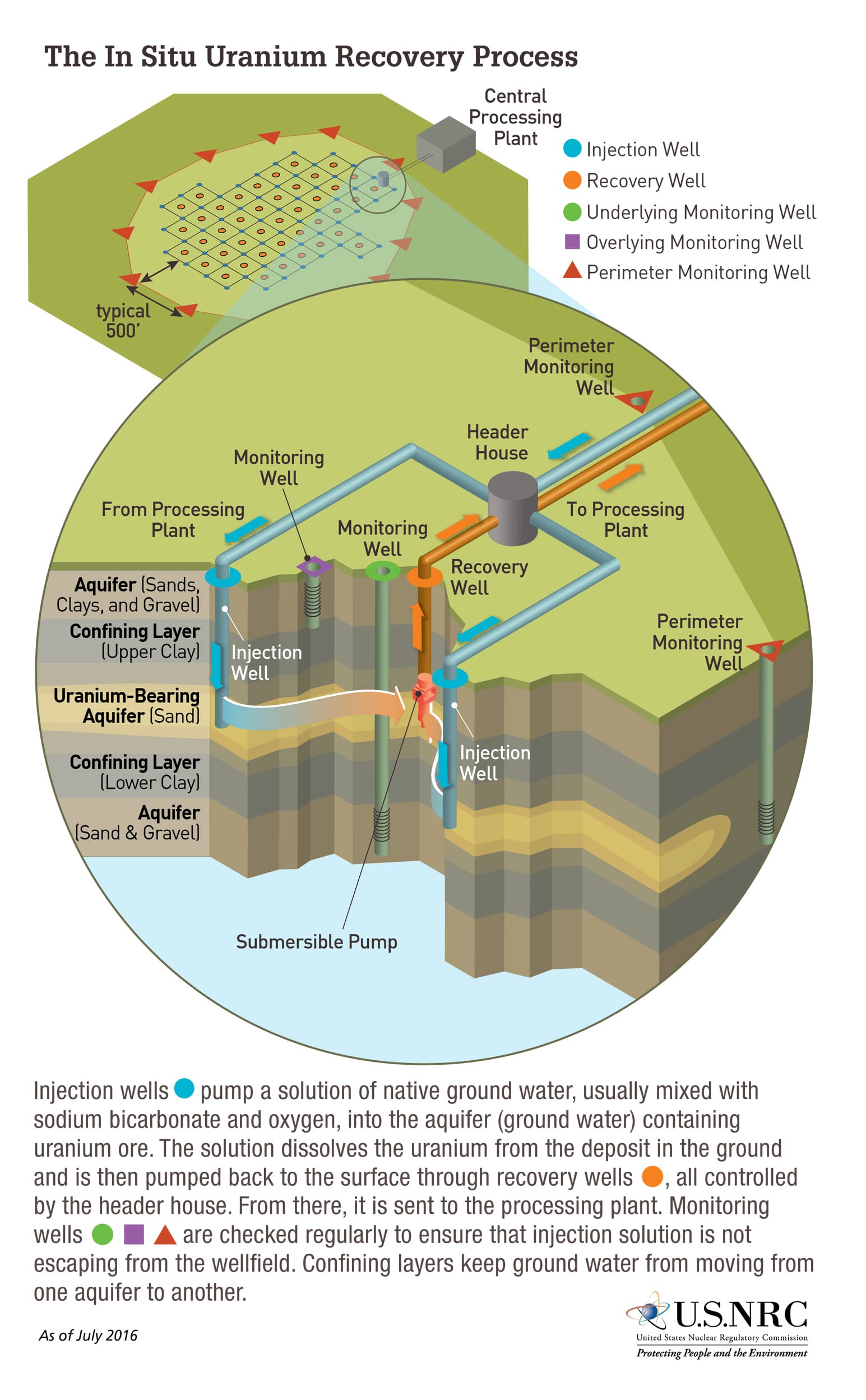

Uranium can be mined through conventional open-pit mining or by “in situ recovery” (ISR), which is similar to fracking and doesn’t require physical excavation of the uranium ore.

In Texas, ISR has become the predominant mining method; no open pit uranium mines are in operation.

This method is one that would be used to mine for uranium ore in Goliad County in the possible near-future. The processing of the uranium mined in Goliad would be done at the Hobson plant, less than 70 miles from Corpus Christi.

Read more about uranium mining in Goliad and across South Texas here.

This technique involves the injection of solvents into aquifer formations rich in uranium ore to dissolve the uranium, which is then pumped to the surface. The uranium is extracted from the solution and processed into “yellow cake,” which is the final product of the ISR method.

Following extraction from a uranium mine, the yellow cake is taken to a conversion plant.

Conversion Plant

In the conversion plant, the yellow cake reacts with fluorine to create uranium hexafluoride. Once the gas is cooled to a liquid, it is put into cylinders, according to the U.S. Nuclear Regulatory Commission.

After five days, it turns into a solid; at that point, it can be shipped to an enrichment plant. This whole process requires energy.

Enrichment Plant

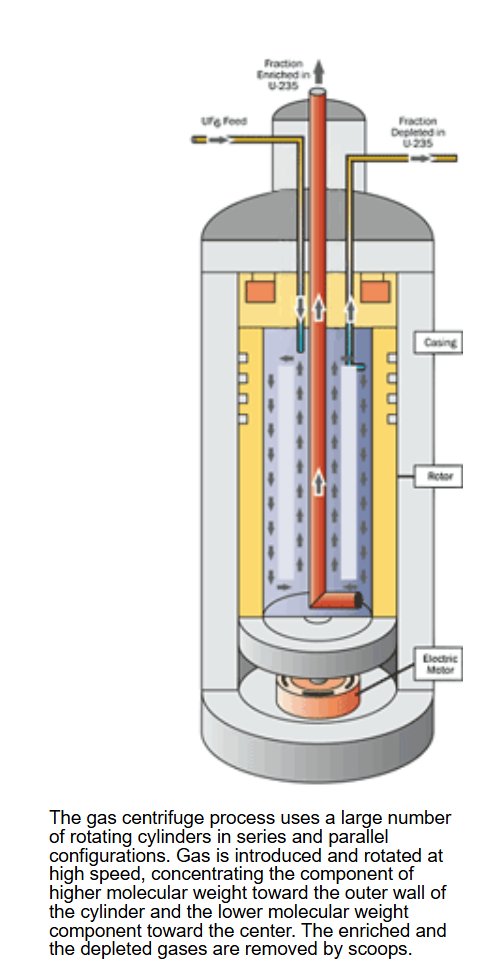

Once at the enrichment plant, the natural uranium needs to be enriched to 3-to-5% to be used as fuel. There are three processes to enrich uranium: gaseous diffusion, gas centrifuge and laser separation.

Gaseous diffusion plants use massive amounts of electricity and are now considered obsolete. At this time, gas centrifuge plants are mostly used. Iran’s nuclear programs use gas centrifuge plants. Laser separation is the newest process, and it was developed by the U.S. Department of Energy (DOE). Regardless of the process, a large amount of energy is required to enrich natural uranium into fuel.

Fuel Fabrication Plant

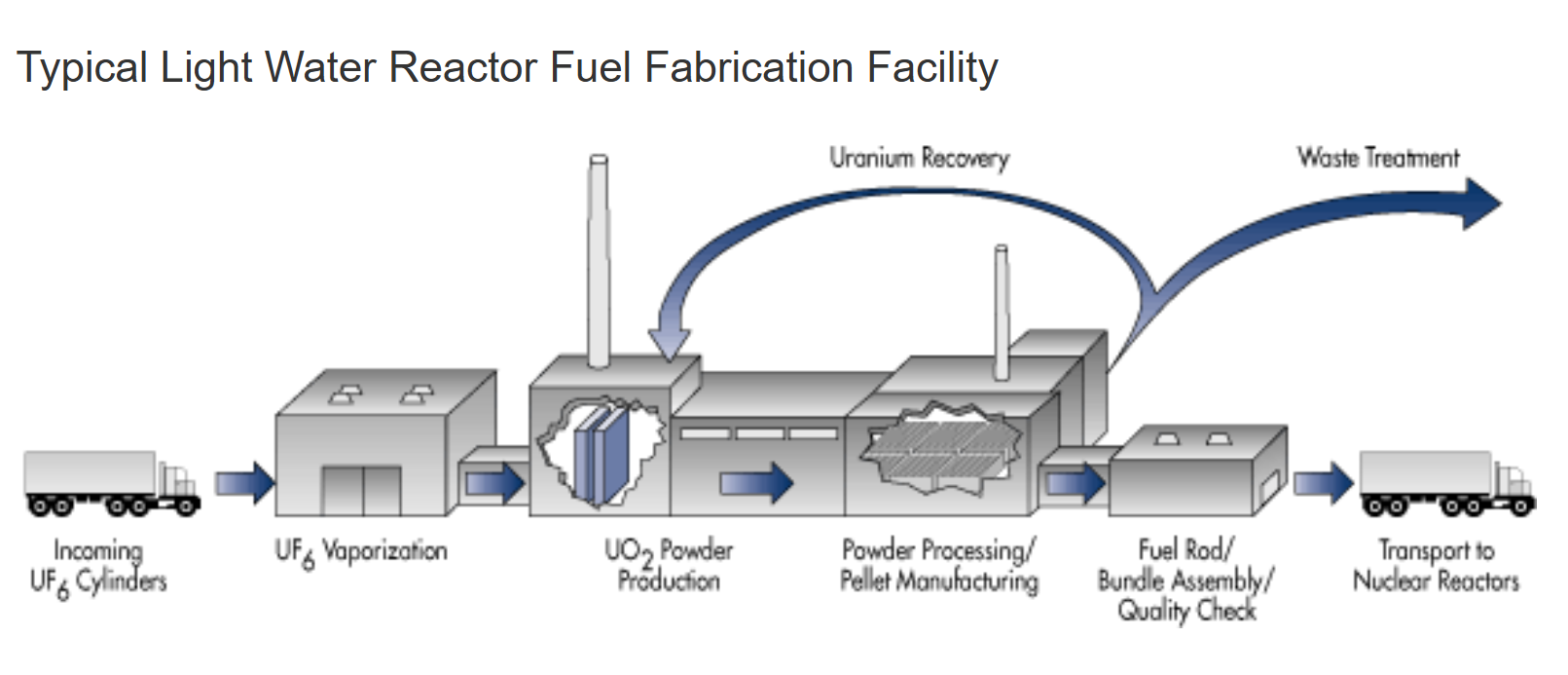

After it’s enriched, the fuel is shipped to a fuel fabrication plant where it’s heated back to its gaseous form. It is then chemically processed to make uranium dioxide powder, which is then compacted into pellets and loaded into tubes to make the fuel assemblies. This final process before the fuel rods are shipped to the reactor sites also requires massive energy sources.

Here are where these factories are located:

Read more about uranium mining in Goliad and across South Texas here.